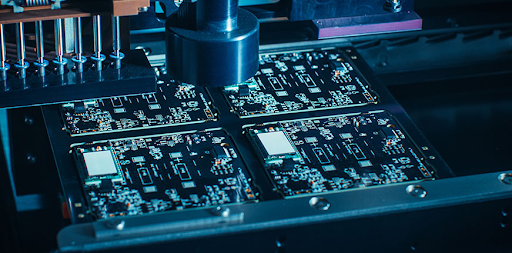

Streamlined PCB Manufacturing and Testing at JHDPCB: Your Reliable Partner

In the fast-paced world of electronics, the need for high-quality, reliable printed circuit boards (PCBs) is crucial. Whether you’re developing a new product or scaling up production, the efficiency and precision of PCB manufacturing and testing can significantly impact your project’s success. JHDPCB stands out as a leader in providing streamlined PCB manufacturing and testing solutions, combining years of experience with advanced technology. This article explores how JHDPCB’s approach ensures top-notch quality and reliability, with a focus on PCB components abbreviations, PCB test abbreviations, PCB test terms, and PCB standards and certification abbreviations.

Streamlined PCB Manufacturing at JHDPCB

At JHDPCB, the manufacturing process is designed to be efficient and precise, ensuring that each PCB meets the highest standards of quality. The company’s streamlined approach encompasses every stage of production, from design and fabrication to assembly and testing.

- Advanced Manufacturing Technology

JHDPCB utilizes state-of-the-art manufacturing equipment to produce high-quality PCBs. This includes advanced etching machines, automated drilling systems, and precision plating equipment. By investing in the latest technology, JHDPCB ensures that every PCB is manufactured with tight tolerances and exceptional accuracy.

- Efficient Design and Prototyping

The design phase is critical for the success of any PCB project. JHDPCB’s experienced team of engineers works closely with clients to optimize PCB designs for manufacturability and performance. The company offers rapid prototyping services, allowing clients to test and refine their designs before moving to full-scale production. This approach helps identify and address potential issues early in the process, saving time and reducing costs.

- Precision Assembly

Once the PCBs are fabricated, they undergo a meticulous assembly process. JHDPCB’s assembly capabilities include both Surface Mount Technology (SMT) and Through-Hole Technology (THT). The use of advanced assembly equipment ensures precise placement and soldering of components, contributing to the overall reliability of the final product.

Comprehensive PCB Testing

Testing is a crucial component of the PCB manufacturing process. JHDPCB employs a range of testing methods to ensure that each PCB meets the required performance and reliability standards. The company’s comprehensive testing approach includes:

- Automated Optical Inspection (AOI)

AOI is used to visually inspect PCBs for defects such as soldering issues, component misalignment, and other manufacturing errors. JHDPCB’s advanced AOI systems provide high-resolution images and detailed analysis, allowing for the identification and correction of defects before the PCBs are shipped to customers.

- In-Circuit Testing (ICT)

ICT is employed to test the electrical functionality of PCBs by checking for shorts, opens, and component values. JHDPCB’s ICT systems are designed to perform thorough and accurate testing, ensuring that each PCB functions as intended.

- X-Ray Inspection

X-ray inspection is used to examine the internal layers of multi-layer PCBs and verify the integrity of solder joints and vias. JHDPCB’s X-ray systems provide detailed images of internal structures, helping to detect issues that may not be visible through other testing methods.

Understanding PCB Terminology

To fully appreciate the complexity and precision of PCB manufacturing and testing, it’s important to understand some key terminology. This includes PCB components abbreviations, PCB test abbreviations, PCB test terms, and PCB standards and certification abbreviations.

- PCB Components Abbreviations

PCB components are often referred to by abbreviations in schematics and design files. Common abbreviations include:

- R: Resistor

- C: Capacitor

- L: Inductor

- D: Diode

- Q: Transistor

- U: Integrated Circuit (IC)

These abbreviations help in identifying and specifying components during the design and manufacturing process.

- PCB Test Abbreviations

PCB test abbreviations are used to describe various testing methods and procedures. Common abbreviations include:

- AOI: Automated Optical Inspection

- ICT: In-Circuit Testing

- FCT: Functional Circuit Testing

- X-Ray: X-Ray Inspection

Understanding these abbreviations helps in recognizing the different types of testing performed to ensure PCB quality.

- PCB Test Terms

Key terms related to PCB testing include:

- Defect: Any issue or imperfection in the PCB that affects its performance.

- Fault: A problem detected during testing, such as a short circuit or open circuit.

- Pass/Fail: A testing outcome indicating whether the PCB meets the required specifications.

Familiarity with these terms aids in understanding the results of various testing procedures and their implications for PCB quality.

- PCB Standards and Certification Abbreviations

PCB standards and certification abbreviations are used to denote industry standards and quality certifications. Common abbreviations include:

- IPC: Institute of Printed Circuits (e.g., IPC-A-600 for PCB Acceptability)

- ISO: International Organization for Standardization (e.g., ISO 9001 for Quality Management Systems)

- UL: Underwriters Laboratories (e.g., UL94 for Flammability Testing)

These certifications and standards ensure that PCBs meet specific quality and safety requirements.

The JHDPCB Advantage

JHDPCB’s streamlined approach to PCB manufacturing and testing offers several key advantages:

- High-Quality Production

By utilizing advanced manufacturing technology and maintaining strict quality control, JHDPCB ensures that each PCB meets the highest standards of quality and performance. The company’s commitment to precision and efficiency translates into reliable and durable PCBs.

- Comprehensive Testing

JHDPCB’s comprehensive testing procedures, including AOI, ICT, and X-ray inspection, provide thorough verification of PCB quality. This multi-faceted approach helps identify and address potential issues, ensuring that only the highest quality PCBs are delivered to customers.

- Expertise and Experience

With 18 years of experience in the PCB industry, JHDPCB has developed a deep understanding of PCB manufacturing and testing. The company’s skilled team of engineers and technicians are well-versed in the latest technologies and best practices, contributing to the overall success of each project.

Conclusion

JHDPCB’s commitment to streamlined PCB manufacturing and testing makes it a reliable partner for your PCB needs. By combining advanced technology, comprehensive testing procedures, and extensive experience, the company delivers high-quality PCBs that meet the highest standards of performance and reliability. Understanding PCB components abbreviations, PCB test abbreviations, PCB test terms, and PCB standards and certification abbreviations provides valuable insight into the complexity and precision of JHDPCB’s processes.

For more information on how JHDPCB can support your PCB manufacturing and testing needs, visit jhdpcb.com and experience the difference of working with a leader in the industry.