Rigid Vs Tuck: Choosing the Best Shipping Box

In today’s era of digitalization, almost every brand is establishing a foothold on technical grounds. Online businesses, offering free or paid shipping services, are setting a trend. Brands seeking a competitive edge need advanced marketing strategies, including top-notch shipping services. When it comes to selecting the best shipping box for the product’s packaging, the choice often boils down to two famous options: Rigid and custom tuck boxes. Each has its own set of perks and limits, making them ideal for different needs and conditions. Let’s delve into a comparative analysis of these two boxes for your better understanding.

Custom Tuck Boxes VS Rigid Boxes: Which Costs More?

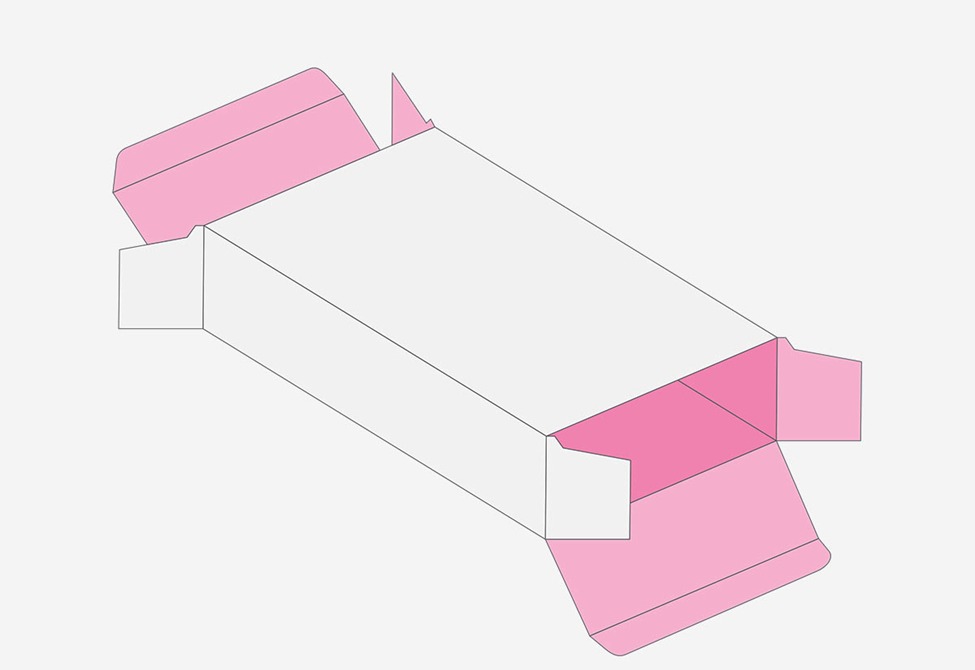

Competitive prices of boxes are crucial for a brand’s growth. Tuck boxes are highly known for their affordability and versatility. They are cheap because of their simpler designs and manufacturing process. Moreover, custom tuck boxes are made from a single cardstock sheet with pre-scored lines for easy assembly and folding. Indeed, these cost-savvy boxes are one of the popular choices for brands seeking solutions to save on costs without compromising on quality.

On the other hand, rigid boxes are synonymous with luxury and durability. They are made from sturdy materials and often involve manual assembly, adding to the labor cost. Studies show that the production of rigid boxes can be three times more costly than that of folding cartons and custom corrugated boxes. These boxes are checked thoroughly for their quality and manufacturing process, including design, pre-press, cutting, creasing, folding, and assembly.

Typically, the price of the boxes varies according to the size, quantity, and customization of the boxes. Rigid boxes, because of their top-notch materials and the labor-intensive production process, carry a higher price tag. For instance, consider their standard price, which is anywhere between $3 to $10 per unit. Whereas, custom tuck boxes might cost from $0.25 to $2 per unit.

Hence, if brands want to save more and don’t need any luxury or extra protection for the product, tuck boxes are the ideal fit for them.

Which Appeals More?

Both these boxes have their unique allure that caters to different marketing segments. Rigid boxes often offer a single type of finish, called the texture fine linen. Whereas, on the other hand, custom tuck boxes can be finished with three types of coatings, matte, gloss, and soft touch lamination. Hence, tuck boxes are more customizable in contrast to the rigid boxes. Moreover, they are also versatile and can be printed with countless colors and textures. Brands often go with them for their aesthetic appeal, which is a critical factor in affecting the customers’ behaviors and making them repeat purchases.

Which is More Durable?

Durability is one of the major features of a shipping box. Rigid and tuck, both vary in their strength and serve different purposes. As the name indicates, rigid boxes are made from a structured and hard frame, enabling them to withstand weight without getting damaged. They get this strength from their manufacturing materials, the thicker paper stock or heavy paper pulp. Moreover, they are precisely cut, folded, and sometimes laminated to add more protection. Hence, they are one of the best options to ship the deluxe items, requiring a high level of security.

Tuck boxes, on the other hand, are potentially thinner and more prone to being compressed. In contrast to rigid boxes, they are made from a single cardstock sheet with pre-scored lines for folding. It makes them less sturdy than rigid boxes. Nevertheless, the lamination on these boxes adds a protective layer to them and offers resistance to moisture and other environmental factors. Hence, when comes to analyzing the box’s durability, custom rigid boxes stand out.

Which is More Convenient and Versatile?

No doubt, the handy boxes are more beneficial for brands and their customers. When comparing rigid and tuck boxes in this aspect, it is found that both offer different perks. However, tuck boxes are highly acknowledged for their easy handling. They are tiny and more compact boxes that can be easily carried or fit into a pocket. This enables them to ship a variety of items, especially the smaller ones that need frequent handling. Moreover, they are easy to assemble and can be quickly opened and closed. This feature adds to their practicality and makes them one of the strongest attractions for retail products.

In contrast, rigid boxes are less versatile in terms of portability. With their large space, they offer ease and a more-structured packaging solution to the brands. Ideally, these boxes are used for subtle and high-end products that need more care during transit and handling. Moreover, these strong boxes are less likely to be damaged during shipping, affirming the product’s safe transfer.

Tuck boxes have many sizes and finish options, making them one of the handy solutions for shipping products. Whereas, rigid boxes are typically used for standard-size items and are not a good option for packing different product sizes.

Which is More Spacious?

To analyze the space of rigid and tuck boxes, one must consider the nature of their construction. Rigid boxes are typically made from hard and unbendable materials, such as glass or metal. Hence, their capacity is fixed and cannot be adjusted. In contrast, tuck boxes are often made from flexible materials, like cardboard or plastic, allowing them to create more space. So, rigid boxes are stable and have a static volume and tuck boxes can expand in size. The choice between shipping boxes is made between rigidity and flexibility, based on the product type and storage needs.

Which Offers More Size Options?

Both these boxes offer a variety of size options to cater to the product’s different needs. Though rigid boxes are large and hard with deluxe looks, they often come in the standard size. Tuck boxes are handy and offer countless size customization options. They are made from foldable materials and can be tailored to the specific sizes of the products they hold.

Recommendations

The choice between rigid and tuck can be affected by many factors. No doubt, both are good shipping options, but one has to go with the box that meets the product’s needs. The following recommendations are crafted for brands to help them make informed decisions:

- Pick a rigid box to add a luxurious touch to the product’s packaging while shipping.

- For the items that demand a snug fit, choose tuck boxes.

- Rigid boxes are ideal for items requiring careful handling during transit.

- Big products, everything from standard poker size to large board games can easily shipped in rigid boxes.

- Prefer tuck boxes for the countless customization options.

- For handy packaging, tuck boxes have an edge over rigid boxes.

- Tuck is the best option for budget-conscious brands.

Therefore, be mindful of choosing the box for the product’s shipping. Consider the product’s needs and then opt for the packaging that aptly fits the item, ensuring its visual appeal and safety.

Final Thoughts

Both rigid and custom tuck boxes have their own qualities. Therefore, one must be aware of the product and brand’s needs to make the right decision. Packaging Mania, a one-stop shop for all shipping boxes, offers 24/7 expert services of its keen staff to help customers make informed buying decisions. Contact now and avail professional services for your brand’s growth.